Why California Modular Builders Are Changing the Housing Market

In a state grappling with a severe housing shortage, soaring construction costs, and unpredictable project timelines, California modular builders are emerging as a transformative force. These professionals are licensed manufacturers and contractors who construct homes, ADUs, and commercial buildings in highly efficient, factory-controlled environments before transporting and assembling them on-site. This innovative method offers a powerful solution to California’s housing crisis by delivering high-quality, code-compliant homes 30-50% faster than traditional site-built homes.

The appeal of modular construction goes beyond speed. It offers predictability in a market known for volatility. With materials sourced in bulk and construction occurring indoors, projects are shielded from weather delays, labor shortages, and unexpected price hikes that often plague conventional builds. This controlled process ensures both cost and timeline certainty, a significant advantage for homeowners and developers alike.

If you’re considering this modern approach and searching for a qualified modular builder in California, a structured vetting process is essential. Here are the key steps to ensure you partner with a reputable professional:

- Verify State HCD Licensing: Your first and most crucial step is to ensure the builder is licensed by the California Department of Housing and Community Development (HCD). This is non-negotiable and guarantees the factory meets state building codes.

- Check MBI Membership: Use the Modular Building Institute member directory to find builders committed to industry best practices and quality standards.

- Confirm General Contractor License: For a seamless, turnkey experience, look for builders who are also licensed general contractors. This means they can manage the entire project from foundation to final finishes.

- Review Specializations: Different builders focus on different project types. Match a builder’s expertise to your specific needs, whether it’s a custom single-family home, a premium ADU, or a multi-family development.

The modular process involves building volumetric sections of your home in a factory, then transporting and assembling them on a prepared foundation. This method ensures consistent quality, drastically reduces construction waste, and minimizes neighborhood disruption. Importantly, state HCD licensed manufacturers are mandated to meet California’s stringent Title 24 energy codes and CalGreen building standards, ensuring every modular building complies with the same regulations as traditional construction—and often exceeds them in performance and energy efficiency.

This guide will provide a comprehensive overview of how modular construction works in California, what it truly costs, and how to confidently select the right builder for your project.

The Modular Advantage: Why Prefab is Perfect for California

Building in California presents a unique trifecta of challenges: exorbitant costs, lengthy construction timelines, and some of the strictest environmental regulations in the nation. California modular builders offer a smarter, more efficient approach that directly confronts these issues, making it an increasingly popular choice for projects of all sizes, from the dense urban landscapes of Los Angeles and San Jose to the sprawling suburbs of the Bay Area.

The primary benefits of modular construction can be summarized in three categories: speed, quality, and sustainability.

Speed and Unparalleled Efficiency: Modular homes can be completed and ready for occupancy 30-50% faster than their site-built counterparts. This remarkable speed is achieved through a parallel workflow. While your home’s modules are being precisely constructed in a factory, site preparation—including excavation, grading, foundation pouring, and utility trenching—is happening simultaneously. In traditional construction, these are sequential steps, each one waiting for the last to be completed. This concurrent process eliminates months of potential delays. The on-site phase, which can take over a year for a traditional home, is condensed to just a few weeks for assembly and finishing touches. This means you move into your new home sooner, saving on rent and carrying costs.

Consistent, Superior Quality: A factory-controlled environment provides a level of precision and quality assurance that is nearly impossible to replicate on an exposed, outdoor construction site. Every component is built indoors by a dedicated team of skilled craftspeople, protected from the elements like rain, wind, and extreme temperatures that can compromise materials and workmanship. Lumber and other materials are not exposed to moisture, preventing the risk of mold, mildew, and warping. Factories use sophisticated jigs, laser guides, and automated equipment to ensure every cut is exact and every wall is perfectly square. This meticulous process results in a tighter, more structurally sound building envelope.

Sustainability and Eco-Friendliness: Modular construction is inherently a greener way to build. Factories optimize material usage through precise planning and bulk purchasing, which can reduce construction waste by up to 90% compared to a typical job site. What little waste is generated is often sorted and recycled or repurposed for other projects. These homes are engineered for superior energy efficiency from the ground up. The tight construction, combined with high-performance windows and precise insulation installation, helps them meet and often exceed California’s strict Title 24 energy standards and CalGreen requirements. This commitment to sustainability not only shrinks your carbon footprint but also translates into significant long-term savings on your utility bills. Furthermore, the condensed on-site schedule means far less disruption to the surrounding neighborhood, with reduced noise, dust, and construction traffic.

A Guide to Vetting California Modular Builders

Choosing the right builder is the single most critical decision in your modular home journey. The time and effort you invest in thoroughly vetting California modular builders at the outset will pay dividends, ensuring a smooth, transparent process and a final product that meets your expectations. While today’s modular builders are capable of creating architecturally stunning homes, comprehensive due diligence is essential to find a true partner for your project.

A reputable builder will be transparent and eager to provide their credentials. Your vetting process should be systematic, starting with licenses and industry affiliations before moving on to their specific experience and client feedback.

The Importance of a State HCD License

In California, any company that manufactures modular homes, ADUs, or other prefabricated structures must hold a valid license from the California Department of Housing and Community Development (HCD). This is not a recommendation; it is the law. An HCD license is your primary assurance of quality and safety. It confirms that the manufacturer’s factory, plans, and quality control processes are subject to regular state inspections. These inspections verify compliance with California’s rigorous building codes for structural integrity, fire safety, electrical systems, plumbing, and energy efficiency. This licensing provides crucial consumer protection, guaranteeing that every module leaving the factory is built to the same high standards as a conventional site-built home. When vetting builders, your first question should always be, “Can you provide your HCD manufacturer license number?” If a builder is evasive or cannot produce a current license, this is a major red flag, and you should walk away.

Leveraging the Modular Building Institute (MBI)

The Modular Building Institute (MBI) is the leading international trade association for the commercial modular construction industry, promoting best practices and innovation across North America. Membership in MBI signals that a builder is a serious professional, invested in their craft and committed to upholding high ethical and quality standards. For homeowners, the MBI website is an invaluable resource. It offers detailed information about modular building in California and provides a searchable member directory. Starting your search with the MBI member directory gives you a pre-vetted list of professionals who are experienced in permanent modular construction and familiar with California’s unique regulatory landscape. Combining MBI membership with HCD and CSLB license verification provides a three-pronged approach to confirming a builder’s qualifications.

Key Questions to Ask Your Builder

Once you’ve verified credentials, conduct a thorough interview. Here are some essential questions to ask:

- Can you provide a complete turnkey service? Clarify if their scope includes site work, foundation, transportation, installation, and final finishing, or if you will need to hire a separate general contractor.

- What is your experience with projects like mine in my specific city/county? Local knowledge is invaluable for navigating permitting and zoning.

- Can I see examples of your past projects and speak with former clients? A confident builder will readily provide references.

- What warranties do you offer? Ask about structural warranties (often 10 years) and warranties on systems and finishes.

- What is your change order process? Understand how design changes are handled and priced once construction has begun.

- Who will be my primary point of contact throughout the project?

Checking References and Contractor Licenses

Always follow through on checking references. Ask past clients about their experience with the builder’s communication, budget adherence, timeline, and post-construction support. If possible, visit a completed home to see the quality of the finish work firsthand. Finally, verify their contractor license through the California Contractors State License Board (CSLB) to ensure it is active and in good standing, with no unresolved complaints.

Decoding the Costs, Codes, and Financing of Modular Homes

Understanding the financial and regulatory landscape of a modular home project is essential for a successful outcome. Many prospective homeowners are initially drawn in by an attractive “kit” price, only to be surprised by the final turnkey cost. To budget realistically and navigate the process with confidence, it’s crucial to break down what to expect.

What is the typical cost for California modular builders?

When you see a price advertised for a modular home, it is almost always for the factory-built modules alone. In California, this base cost for the “prefab kit” typically ranges from $40 to $84 per square foot. This price includes the constructed modules with standard finishes, delivered from the factory.

However, the all-in, move-in ready turnkey cost is the number you need to budget for. This final cost is usually 3 to 5 times the initial kit price. This significant multiplier covers all the other essential hard and soft costs required to complete the project. A comprehensive quote from your California modular builders should itemize these expenses, which include:

- Soft Costs: Architectural and engineering fees, soil reports, surveying, and city/county permit fees.

- Site Preparation: Demolition of existing structures, grading, excavation, and utility trenching (water, sewer/septic, gas, electricity).

- Foundation: Engineering and construction of a permanent foundation, which is required by law for modular homes.

- Transportation & Installation: Shipping the modules from the factory to your property and the cost of a crane and crew to set the modules onto the foundation.

- On-Site Finishing (Button-Up): The labor and materials to connect the modules, complete roofing and siding, finish drywall seams, and install flooring and final paint.

- Utility Connections: The physical hook-up of your home to public utilities or the installation of septic and well systems.

- Additional Site Work: Driveways, walkways, landscaping, decks, and garages.

Be aware that custom designs, high-end finishes, and smaller homes (under 1,000 sq. ft.) often have a higher cost per square foot due to fixed costs being spread over a smaller area.

Navigating California’s Building Codes

Modular homes in California are not a loophole to avoid stringent building standards; they are held to the exact same high standards as traditionally built homes. There are no shortcuts. California modular builders must design and construct homes that comply with a multi-layered system of regulations:

- California Building Code (CBC): This governs all aspects of structural integrity, fire safety, and occupant health.

- Title 24: These are California’s strict energy efficiency standards. Compliance means your home will have superior insulation, high-performance windows, and efficient heating, cooling, and lighting systems, resulting in lower utility bills.

- CalGreen: This is California’s green building code, which mandates sustainable practices like using low-VOC paints, water-conserving plumbing fixtures, and construction waste diversion.

The permitting process is unique. The factory-built portion of the home is inspected and approved by the state’s HCD, while all site work, including the foundation and final assembly, is inspected and permitted by your local city or county building department (e.g., in Mountain View, Los Angeles, or Sunnyvale). An experienced builder is crucial for managing this dual-approval process efficiently.

Financing Your Modular Home Project

Financing a modular home is very similar to financing a traditional, site-built home. Because they are built on permanent foundations and are legally classified as real property, lenders treat them as conventional real estate. Appraisals are based on comparable site-built homes in the area.

The most common financing vehicle is a construction-to-permanent loan. This single-close loan funds the project in stages (called “draws”) as construction milestones are met—for example, a draw for the foundation, another for the delivery of modules, and a final one upon completion. Once the home is finished and a certificate of occupancy is issued, the loan automatically converts into a standard mortgage. Many modular builders have established relationships with lenders who are experienced with this process, which can help streamline approvals. The U.S. Department of Housing and Urban Development also provides valuable resources on housing financing. It is wise to get pre-approved for a loan early in your planning process to establish a clear and realistic budget.

From ADUs to Estates: Modular Building Types and Solutions

The versatility of modular construction is one of its most compelling attributes. From a compact, income-generating ADU in a Los Angeles backyard to a sprawling custom estate in the Bay Area, California modular builders can deliver projects of nearly any scale and architectural style with unparalleled efficiency. This flexibility makes modular an excellent choice for a wide range of housing needs, including single-family homes, Accessory Dwelling Units (ADUs), and multi-family developments.

| Project Type | Typical Size Range | Primary Use | Key Regulations |

|---|---|---|---|

| Single-Family Modular Homes | 400 – 3,000+ Sq. Ft. | Primary residence, custom homes | California Building Code, Title 24, CalGreen, HCD |

| Accessory Dwelling Units (ADUs) | 400 – 1,200 Sq. Ft. | Rental income, guest house, in-law suite | Local ADU ordinances, California Building Code, HCD |

| Modular Multifamily Housing | Varies by project (e.g., 2-40+ units) | Rental properties, affordable housing, student housing | California Building Code, HCD, local zoning |

Custom Homes and Premium Designs

Dismiss any outdated notions of cookie-cutter prefabs. Today’s California modular builders are at the forefront of creating stunning, architecturally significant custom homes that rival any site-built luxury residence. By collaborating with in-house designers or your own architect, you can design a home that perfectly reflects your personal style, from a sleek Mid-Century Modern retreat to a warm, inviting Craftsman-style family home. The process often begins with advanced 3D modeling, allowing you to virtually walk through and refine your home before a single piece is built. You retain full control over every material selection, including premium hardwood flooring, designer tile, custom cabinetry, high-end appliances, and smart home features. Because these high-value finishes are installed in a controlled factory setting by specialized craftspeople, the quality of workmanship and fit-and-finish is consistently high and protected from on-site damage.

The Rise of Premium ADUs in California

Accessory Dwelling Units (ADUs) have become a cornerstone of California’s strategy to increase housing density. The market for premium ADUs is particularly strong, as homeowners recognize them as powerful investments and flexible living solutions. A premium ADU goes beyond a basic backyard cottage, incorporating features that command higher rent and provide greater comfort:

- Luxury Finishes: Features like quartz countertops, custom cabinetry, spa-like bathrooms with high-end fixtures, and durable, stylish flooring.

- Smart Home Technology: Integrated systems for lighting, climate control, security, and entertainment that appeal to tech-savvy renters.

- Sustainable and Resilient Design: Options like solar panels, high-efficiency HVAC systems, and superior insulation that far exceed Title 24 energy standards, resulting in near-zero utility bills.

These high-end features make premium ADUs highly desirable for long-term renters in competitive markets like San Jose and Mountain View, generating significant passive income. They also serve as excellent aging in place solutions, allowing elderly parents to live independently but close to family. Modular construction is ideal for this, easily accommodating single-level layouts, wider doorways, zero-threshold showers, and other accessibility features. A well-designed, high-quality ADU can substantially increase your property value, making it a compelling and multifaceted investment.

Modular Solutions for Multifamily Housing

Beyond single-family residences, modular construction is proving to be a game-changer for developers of multifamily housing. The speed of modular allows projects to be completed and begin generating revenue months or even years ahead of conventional construction schedules. This is a massive financial advantage. For affordable housing projects, the cost predictability and reduced construction time enable non-profits and government agencies to build more units with limited funds. In urban areas, modular is being used to build everything from small duplexes and fourplexes to large-scale apartment buildings and student dormitories. The reduced on-site activity also minimizes disruption in dense, populated neighborhoods, making it a more community-friendly way to build.

Frequently Asked Questions About California Modular Builders

Embarking on a modular home project can feel like entering a new world, and it’s natural to have questions. Here are clear, direct answers to some of the most common inquiries we receive from homeowners across California.

How long does it take to build a modular home in California?

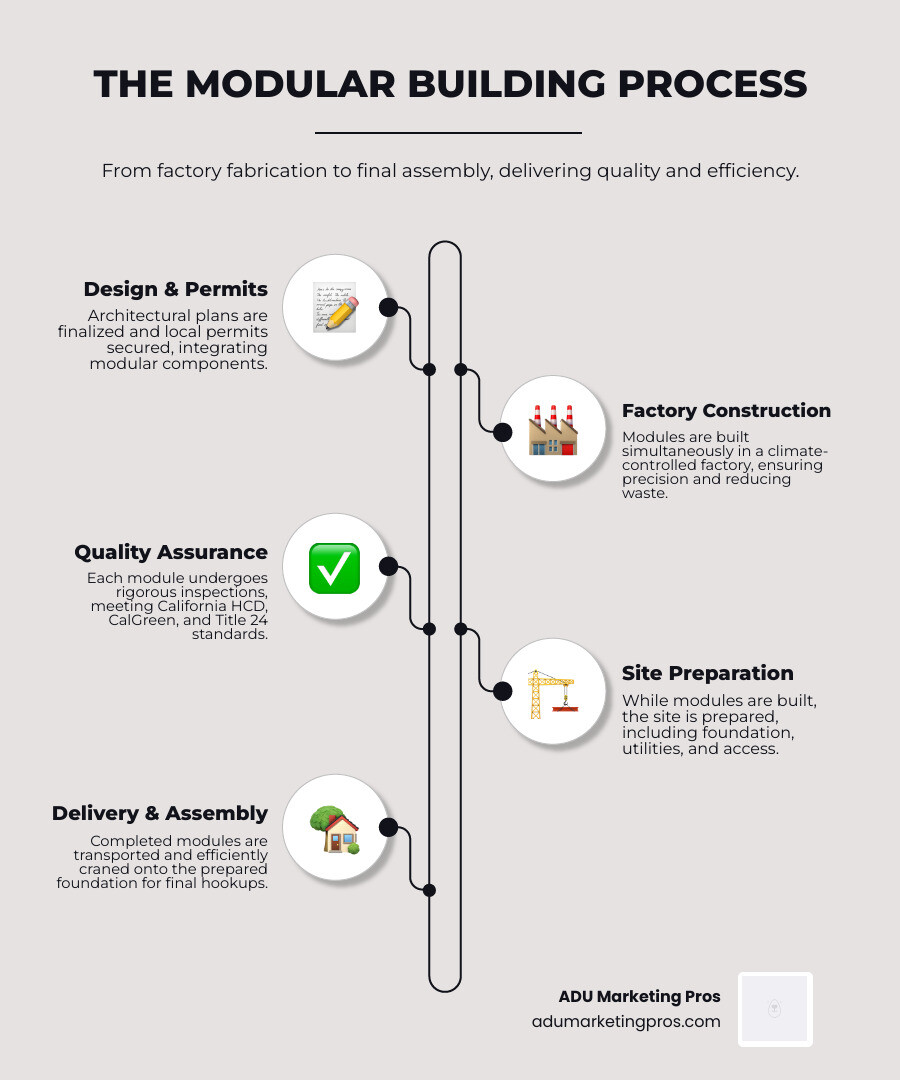

A primary advantage of modular construction is its accelerated timeline. A typical modular home project in California takes 6 to 12 months from start to finish. This is significantly faster than a traditional site-built home, which often takes 12 to 24 months or longer. The process can be broken down into three overlapping phases:

- Phase 1: Design & Permitting (2-6 months): This involves finalizing your home’s design, engineering, and submitting plans for approval. An experienced California modular builder who knows the local jurisdiction can help streamline this often-bureaucratic phase.

- Phase 2: Factory Construction & Site Prep (1-3 months): This is where the magic of the parallel process happens. While your home’s modules are being built in the factory, your foundation is being excavated and poured on-site.

- Phase 3: Installation & Finishing (1-3 months): The factory-built modules are transported to your site and typically set onto the foundation by a crane in just one or two days. The final phase involves the on-site work to connect the modules, finish the roof and siding, and complete interior details like flooring and paint.

The exact timeline can vary based on design complexity, factory backlogs, and the efficiency of your local building department, but it is consistently and predictably faster than traditional methods.

Are modular homes a good investment in California?

Yes, absolutely. This is a common misconception rooted in the past. Modern modular homes are built to the exact same California Building Code as site-built homes, are appraised using the same standards, and appreciate in value identically. Lenders and real estate agents treat them the same as any other form of single-family real estate. In fact, one could argue they are a superior investment for several reasons. The quality of construction is often higher due to the controlled factory environment, resulting in a more durable and resilient structure. They are engineered to be incredibly sturdy to withstand transportation and craning. Furthermore, their inherent energy efficiency, designed to meet or exceed strict Title 24 standards, leads to lower homeownership costs over the long term, which is an attractive feature for future buyers.

What’s the difference between a modular and a manufactured home?

This is a critical distinction that every prospective buyer must understand. While both are built in a factory, they are entirely different products governed by different codes and regulations.

- Building Codes: Modular homes are built to the same state and local California Building Code (CBC), Title 24, and CalGreen standards as a site-built home. Manufactured homes (formerly known as mobile homes) are built to a national, federal HUD code.

- Foundation: Modular homes are permanently affixed to a perimeter foundation and are legally considered real property. Manufactured homes are built on a steel chassis, which may or may not be placed on a permanent foundation.

- Customization & Design: Modular homes offer nearly limitless design flexibility and customization, comparable to site-built homes. Manufactured homes typically offer a more limited set of standardized floor plans and finishes.

- Financing & Appraisal: Modular homes qualify for conventional construction loans and mortgages, just like a site-built home. Manufactured homes often require specialized chattel loans or other types of financing, though this is changing.

When we refer to California modular builders, we are exclusively discussing professionals who create permanent, high-quality homes that are legally and structurally equivalent to traditional houses.

Can I customize the floor plan of a modular home?

Yes. The vast majority of modular builders offer extensive customization. You are not limited to a catalog of pre-set designs. Most builders have in-house design teams that can work with you to modify one of their existing plans or create a completely custom floor plan from scratch. You can also bring plans from your own independent architect. The primary constraint is that the design must be divisible into transportable sections (modules). A good designer can help you achieve your desired layout while working within these logistical parameters, allowing you to control room sizes, window placement, and overall flow.

How does the permitting process work for a modular home?

The permitting process is a key area where an experienced modular builder adds value. It involves a dual-approval system:

- State (HCD) Approval: The plans for the factory-built portion of the home are reviewed, approved, and inspected by the California Department of Housing and Community Development (HCD). This state-level approval is valid across all counties.

- Local (City/County) Approval: Your local building department reviews and approves the plans for all site-specific work. This includes the foundation design, utility connections, site grading, and how the home is placed on the lot to meet zoning setbacks. They will also inspect all of this on-site work as it is completed.

An experienced builder manages both tracks simultaneously to ensure a smooth and efficient process, saving you from navigating the complexities of two different regulatory bodies.

Conclusion: Building Your Future with Modular Construction

As California’s housing landscape continues to present challenges, modular construction stands out as a smarter, faster, and more sustainable path to homeownership and real estate investment. You now have a clear understanding that California modular builders can deliver high-quality homes 30-50% faster than traditional methods, all while offering predictable costs and superior quality control born from a factory setting. These homes are not just an alternative; they are an evolution, perfectly aligning with California’s progressive environmental values by meeting and often exceeding the stringent Title 24 and CalGreen standards.

Most importantly, you are now equipped with the knowledge to properly vet a builder, prioritizing a valid State HCD license, checking for MBI membership, and asking the right questions to ensure transparency and competence. Whether your vision is a stunning custom home in Palo Alto, a high-yield premium ADU in Los Angeles, or an innovative multi-family project in San Jose, modular construction provides the design flexibility and logistical efficiency to bring it to life. It is a powerful, practical solution to the state’s housing needs, empowering homeowners and investors to build for a better future.

For builders and contractors operating in this expanding market, connecting with these informed and motivated customers is paramount. As demand for quality modular construction continues to rise, standing out from the competition requires strategic marketing that effectively communicates expertise and trust.

At ADU Marketing Pros, we specialize in helping construction and architecture firms attract high-quality leads in the competitive ADU and modular building space. If you are ready to grow your business by reaching customers who value quality and are prepared to invest, we can help. Learn more about prefab ADUs in Los Angeles and discover how targeted digital marketing can transform your lead generation and elevate your brand.