Why Prefab Granny Flats Are Reshaping Modern Housing

A granny flat prefab home represents a paradigm shift in residential construction. It is a small, fully functional, self-contained dwelling unit meticulously crafted in a factory environment and then transported to your property for final assembly. These accessory dwelling units (ADUs) are rapidly becoming the go-to solution for homeowners seeking a faster, more cost-effective, and predictable alternative to the uncertainties of traditional, on-site construction. Imagine the core structure of your new home—walls, floors, roof, with plumbing and electrical systems pre-installed—being up to 90% complete before it even reaches your backyard. This streamlined process allows for an astonishingly quick on-site installation, often in as little as one to three days, fundamentally revolutionizing a construction timeline that once spanned many disruptive months.

Quick facts about prefab granny flats:

- Size: Typically range from 400 to 1,200 square feet. Layouts are incredibly versatile, from efficient studios perfect for a single person to spacious one or two-bedroom models that can comfortably accommodate a couple or small family. This range allows for tailored solutions that fit both the property’s constraints and the homeowner’s specific needs.

- Cost: Kit prices can start as low as $25,000 and go up to $100,000 or more, depending on size and finishes. It’s crucial to understand this price typically excludes ‘soft’ costs and ‘site’ costs, which include permits, design fees, site preparation, foundation, utility hookups, and final installation. The total ‘all-in’ cost is therefore higher but often more predictable than traditional builds.

- Speed: The entire project timeline, from start to finish, can be up to 80% faster than traditional methods. While the home is built in the factory over several weeks, the on-site disruption is minimal. The core installation is often completed in just 1-3 days, followed by a few weeks for utility connections and final finishing.

- Quality: Constructed to meet or exceed the same local and state building codes as any site-built home. The factory environment enables stringent quality control measures at every step, from precision-cut framing to protected material storage, resulting in a tighter, more durable, and energy-efficient structure.

- Uses: Their flexibility makes them ideal for a wide range of applications: housing aging parents (the original ‘granny flat’ concept), providing independence for adult children, creating a detached home office, accommodating long-term guests, or generating significant monthly rental income to offset a mortgage.

The housing landscape, particularly in high-cost states like California, is undergoing a seismic shift. Decades of underbuilding have created a critical housing shortage, sending prices and rents soaring. Combined with the rising cost of materials and a shrinking skilled labor pool, traditional construction is becoming untenable for many. This perfect storm of challenges, alongside a growing cultural demand for flexible living arrangements fueled by the remote work revolution, has created an urgent need for innovation. In response, state and local governments have dramatically eased regulations around accessory dwelling units, recognizing them as a powerful tool for adding density gently into existing neighborhoods. The granny flat prefab home has emerged as the most practical, scalable, and efficient solution. It directly addresses the need for multigenerational living, provides a viable pathway to more affordable housing options, and delivers the flexible space that modern families and professionals require. Organizations like Home for All are championing these and other innovative housing models to tackle the affordability crisis head-on in communities across the country.

Prefabricated construction is the engine driving this housing revolution. By moving up to 90% of the building process into a controlled factory environment, this method systematically eliminates the chronic issues that plague traditional on-site building. Weather delays, which can add weeks or months to a project, become a non-issue. Material waste is drastically reduced from the industry average of 15-20% down to as little as 2% through computer-optimized cutting and material reuse. The entire process is streamlined and accelerated. A project that would typically consume six to eight months of a homeowner’s life—filled with daily noise, dust, and a constant stream of contractors—can now be completed in a fraction of the time, with the on-site disruption lasting for weeks instead of the better part of a year.

For ADU construction firms, architects, and developers, this shift isn’t just a passing trend—it’s a fundamental change in the market. Today’s homeowners are more educated and proactive than ever, armed with extensive online research about prefab options before they even make the first inquiry. They are no longer just looking for a builder; they are seeking a trusted advisor who can provide clear, honest, and expert guidance through the complexities of permitting, site prep, and installation. This guide is designed to cut through the noise and confusion, providing a comprehensive overview of what prefab granny flats are, how they stack up against other construction methods, and what the journey looks like from the initial design concept to the final move-in day.

This evolving market presents a significant opportunity for builders and architects who can adapt their marketing and sales processes. The key is to build trust by leading with education. With the standardized scopes and predictable timelines inherent in prefab construction, firms can create clear value propositions that resonate with savvy clients. Instead of competing solely on price, successful firms are positioning themselves as experts. They use targeted content—through SEO, informative articles, and clear project galleries—to guide homeowners through the process. This educational approach attracts higher-quality leads and helps convert interest into signed contracts by demonstrating expertise and transparency, which are paramount in the California ADU market, from Los Angeles and San Diego to the San Francisco Bay Area.

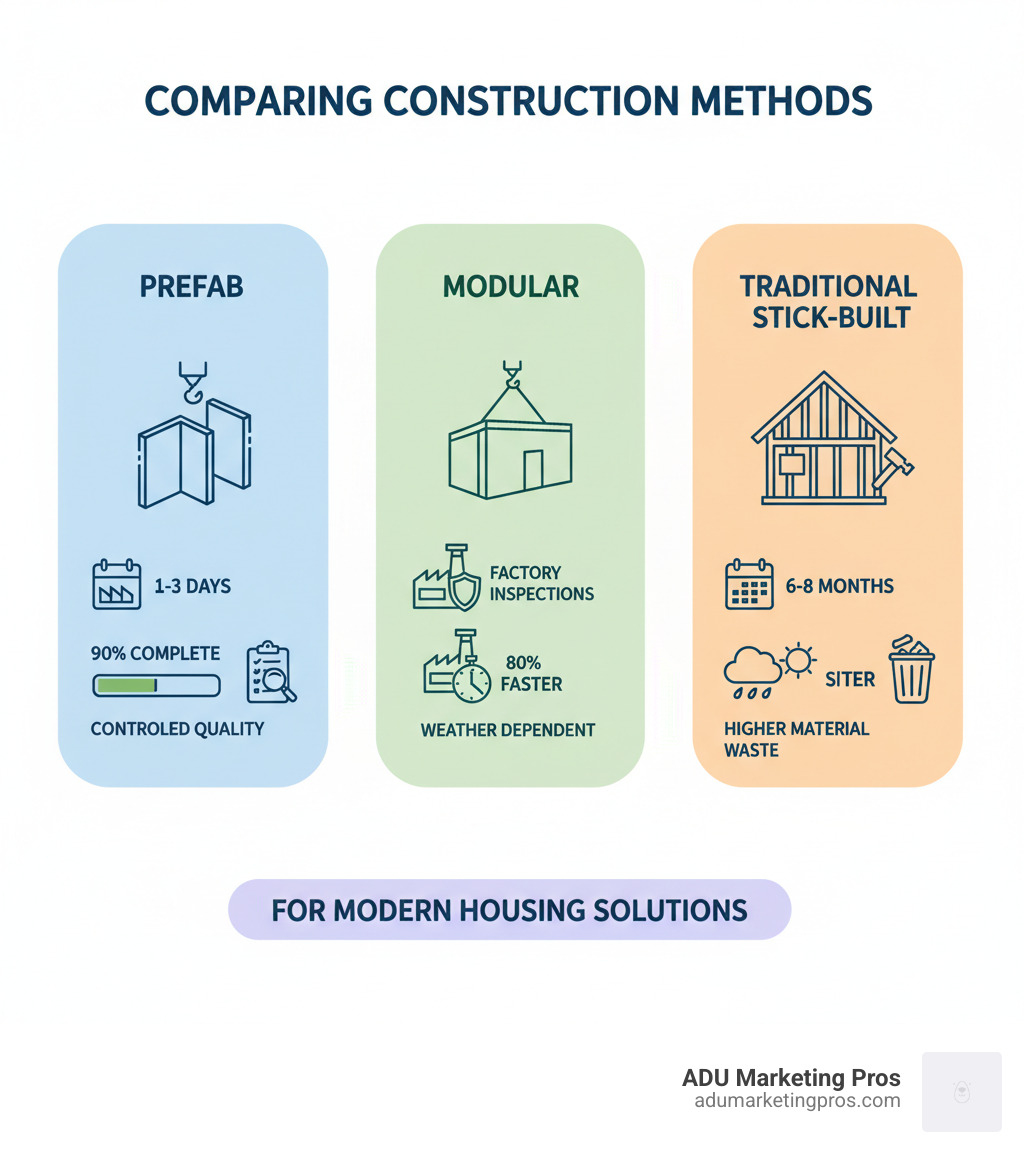

In the following sections, we’ll dig deeper into the tangible advantages of prefab ADUs, explore the potential challenges and how to navigate them, and highlight the critical decisions you or your clients will face. Understanding this landscape is no longer optional; it’s essential for any homeowner considering an ADU and for any building professional looking to thrive in the modern housing market. Use the infographic below to quickly compare prefab, modular, and traditional stick-built methods at a glance before we explore these topics in greater detail.

What Exactly is a Prefab Granny Flat?

When you hear someone mention a granny flat prefab home, they’re talking about a sophisticated, modern housing solution that is revolutionizing how we add living space to our properties. This isn’t a simple backyard shed or a flimsy mobile home; it’s a high-quality, permanent dwelling that’s changing the game in California cities from Los Angeles and San Diego to the San Francisco Bay Area, including San Jose, Sunnyvale, Palo Alto, Mountain View, and Menlo Park. To truly grasp its impact, it’s essential to understand what “prefab” really means and how it differs from other construction methods like modular and traditional stick-built homes.

Defining the Modern Backyard Home

A prefabricated home is one where the primary structural components are built in a factory setting. Instead of a construction crew descending on your property for months with raw lumber and hammers, the majority of the skilled labor happens off-site in a controlled environment. Think of a large, climate-controlled facility where craftspeople use precision equipment and automated systems to build walls, floors, and roof systems in panels or sections. These components often include pre-installed windows, insulation, and even rough-in electrical and plumbing. Once these components are finished and have passed rigorous quality inspections, they are carefully loaded onto trucks, transported to your property, and craned into place for final assembly.

It’s a process that marries the efficiency and precision of modern manufacturing with the quality, permanence, and aesthetic appeal of traditional housing. Every granny flat prefab home is engineered and constructed to meet the very same rigorous local and state building codes—such as the California Building Code—as a conventional site-built home. They are not a separate, lesser class of building; they are simply built in a smarter, more efficient way.

Legally, these homes fall under the category of Accessory Dwelling Units (ADUs). An ADU is a secondary residential unit with its own kitchen and bathroom, built on the same lot as a primary residence. While the term “granny flat” evokes a cozy space for an aging parent—still a wonderful and popular use—today’s ADUs are incredibly versatile. They are often called in-law suites, casitas, garden cottages, or backyard homes, reflecting their diverse functions as rental properties, home offices, or guest houses. For a comprehensive overview of state-level guidance, which has been instrumental in the ADU boom, the California Department of Housing and Community Development’s ADU page is an excellent and authoritative resource.

It’s also crucial to distinguish permitted ADUs from ‘tiny houses on wheels.’ While both are compact living solutions, the distinction is critical for legal and financial reasons. Tiny houses are typically built on a trailer chassis to remain mobile, are often under 400 square feet, and are regulated as recreational vehicles (RVs), not permanent housing. In contrast, ADUs are permanent structures built on a foundation, fully permitted as a legal dwelling, and can be financed with traditional mortgages. They add legal, appraisable value to your property. Our guide on ADU vs Tiny House explores these important differences in greater detail.

The true power of prefab construction lies in the controlled factory environment. Production schedules are not at the mercy of rain, snow, or extreme heat. Expensive materials are stored safely indoors, protected from weather damage and job site theft. Workers operate in safer, more ergonomic conditions with specialized tools at their disposal. This consistency and control translate directly into higher build quality, predictable timelines, and a significantly smoother, less stressful experience for the homeowner.

Prefab vs. Traditional Stick-Built Construction

Understanding the fundamental differences between a granny flat prefab home and a traditional stick-built home is key to appreciating why so many homeowners and builders are making the switch. These differences impact every phase of the project, from the initial budget and financing to the final timeline and long-term performance of the home.

| Feature | Prefab Granny Flat | Traditional Stick-Built |

|---|---|---|

| Timeline | 80% faster; on-site install in 1-3 days | 6-8 months of on-site construction |

| Cost | Lower labor costs; reduced waste | Higher labor expenses; more material waste |

| Quality Control | Factory inspections at every stage | On-site inspections; weather exposure |

| Environmental Impact | Minimal waste; efficient material use | 15-20% material waste typical |

Timeline: The most dramatic and celebrated advantage of prefab is speed. A traditional construction project is linear and sequential: nothing can be framed until the foundation is fully cured, and interior work can’t begin until the structure is ‘dried in.’ This process takes months and is vulnerable to delays at every step. A prefab project, however, uses a parallel workflow. While your local contractor is handling the 4-6 week process of site preparation, grading, and pouring the foundation, your home is simultaneously being built in the factory. This overlap is what cuts the overall project time by months, not just weeks. The on-site disruption is also radically minimized. Instead of half a year or more of noise, debris, and parking issues, the main event is a few days of assembly, followed by a few weeks of final utility hookups, seam finishing, and landscaping.

Cost: Prefab construction offers significant and multifaceted cost efficiencies. Factories purchase materials in bulk, securing better pricing than a single-project contractor can. The controlled environment and specialized labor lead to faster, more efficient work, reducing the total number of expensive labor hours. Furthermore, the dramatic reduction in construction time means lower carrying costs on any construction loans. Perhaps most importantly, prefab offers cost certainty. The price of the factory-built unit is fixed, protecting homeowners from the budget overruns common in stick-built projects due to unforeseen on-site problems or material price spikes. This predictability is also highly attractive to lenders. Finally, minimizing material waste through precision factory cutting means you aren’t paying for lumber and other materials that just end up in a landfill.

Quality Control: A factory setting allows for a level of quality control that is nearly impossible to replicate on an open-air construction site. Components are built in heavy steel jigs that ensure every wall is perfectly square and every angle is precise. Inspections are performed by dedicated quality managers at multiple stages of the process—framing, electrical, plumbing, insulation—before the walls are even closed up. This is a stark contrast to on-site builds, where components are exposed to rain, sun, and humidity, which can lead to warped lumber, mold growth, and other imperfections. Moreover, factory-built homes are often engineered to be stronger, as they must withstand the stresses of being transported by truck and craned into place. This means extra reinforcement, stronger connections, and a more robust structure that can better withstand seismic events and extreme weather.

Environmental Impact: The eco-friendly aspect of prefab is a major draw for conscientious homeowners and builders. Traditional construction sites are notoriously wasteful; it’s common for 15-20% of materials to be discarded, contributing tons of debris to local landfills. In a factory, materials are optimized with advanced software to maximize usage, and off-cuts from one project can often be repurposed for another, reducing waste to a minimum. The construction process also has a smaller local impact, with less noise pollution and traffic in the neighborhood. Beyond the build, the tighter construction achieved in a factory results in a more energy-efficient building envelope. This means fewer air leaks, better insulation performance, and significantly lower heating and cooling costs for the life of the home, reducing its overall carbon footprint.

While traditional construction certainly has its place, especially for highly complex or unusual custom designs that don’t lend themselves to factory production, the prefab approach offers a compelling package of speed, savings, and superior quality that is hard for most homeowners and builders to ignore. For ADU builders and architects, embracing these predictable processes translates directly into clearer project scopes, more transparent timelines, and powerful marketing narratives. It allows them to showcase their expertise in managing a modern, efficient process, winning clients who value quality, certainty, and a less disruptive building experience.