Why Modular ADUs Are Changing Backyard Living

A modular adu is a factory-built accessory dwelling unit constructed in sections (modules) off-site, then transported and assembled on your property. This isn’t just a minor tweak to the construction industry; it’s a fundamental shift in how we think about building homes. Unlike traditional stick-built projects, which are often plagued by unpredictable delays, weather issues, and spiraling cost overruns, modular ADUs are built in highly controlled factory environments. This modern approach offers homeowners faster timelines, predictable costs, and a level of quality control that is difficult to achieve on an open-air construction site.

Across California, from the dense urban neighborhoods of Los Angeles to the sprawling suburbs of the Bay Area, homeowners are embracing this method. The reasons are clear: housing costs continue to soar, and recent changes in state and local regulations have made it easier than ever to build backyard homes. The debate is no longer just about different construction methods; it’s a crucial conversation about speed, cost, quality, and sustainability. For anyone considering adding a rental unit, an in-law suite, or a home office, understanding the modular advantage is essential.

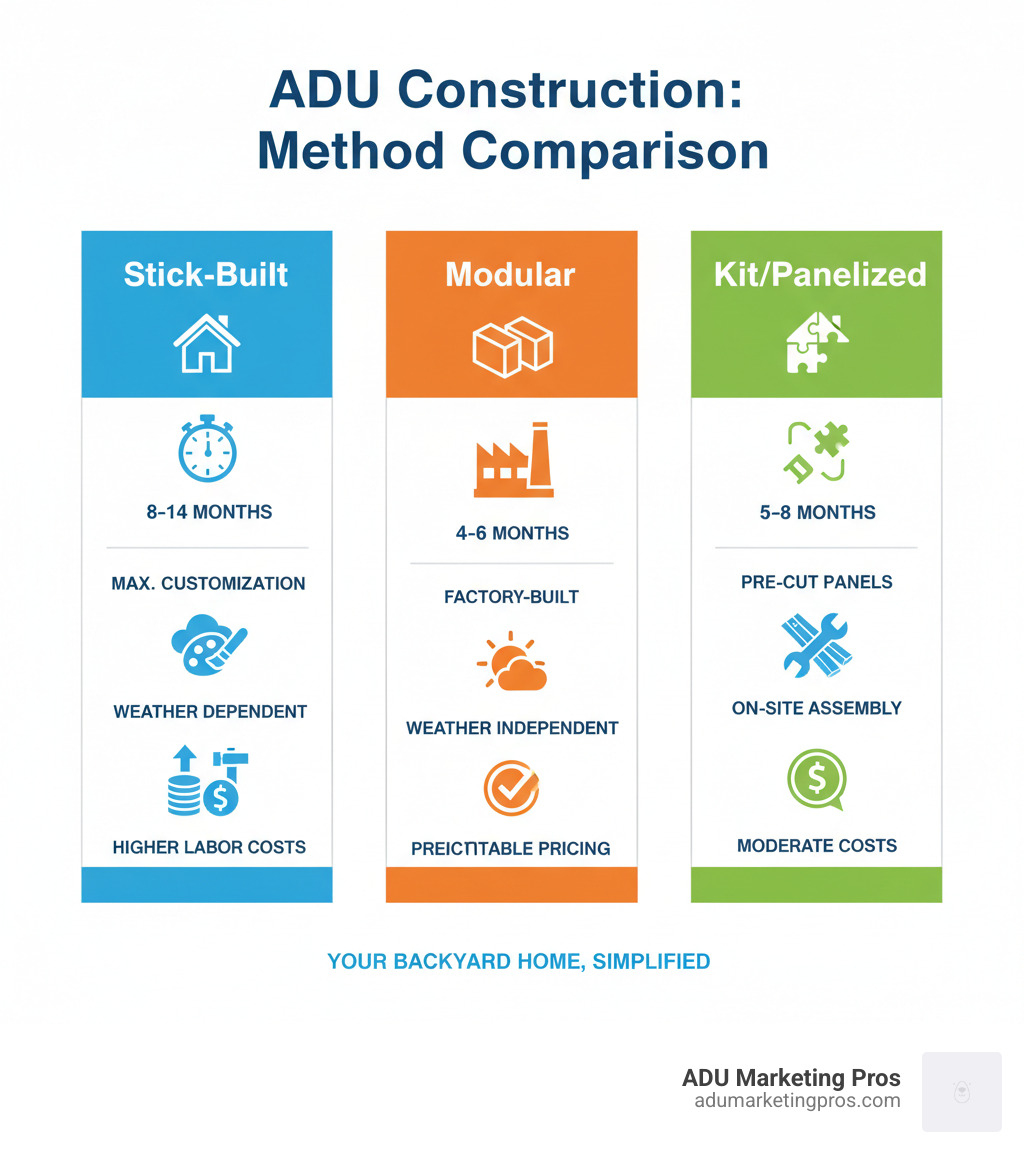

Quick comparison of modular vs. traditional ADU construction:

| Factor | Modular ADU | Stick-Built ADU |

|---|---|---|

| Timeline | 4-6 months (predictable) | 8-14 months (variable) |

| Cost | $200-$600/sq ft (often fixed) | $300-$800/sq ft (prone to overruns) |

| Weather delays | Minimal (90% factory-built) | Frequent (on-site exposure) |

| Quality control | Rigorous factory inspections | Varies by contractor and crew |

| Waste Generation | Significantly reduced | High (material cut-offs, etc.) |

| Customization | Moderate to high | Maximum (at a high cost) |

These numbers tell a compelling story. By shifting the bulk of construction into a specialized facility, modular ADUs can be up to 25% more affordable than similar stick-built units. The timeline is even more dramatic, with potential for 50% shorter lead times and a 33% faster installation process once the unit arrives on site. This means you can start generating rental income or move a family member in months sooner, turning a construction project into a performing asset in record time.

Defining the Terms: Modular, Prefab, Kit, and Stick-Built ADUs

When you start exploring the world of backyard homes, you’ll quickly encounter a dizzying array of construction jargon. Terms like prefab, modular, panelized, and stick-built are often used interchangeably, but they describe fundamentally different approaches to where and how your ADU gets built. Understanding these distinctions is the first step in choosing the right path for your property, budget, and timeline. Let’s clarify the key differences.

Traditional Stick-Built ADUs

This is the classic construction method that most people picture: a team of builders arrives at your property and constructs the ADU from the ground up, piece by piece (or “stick by stick”), in your backyard. It’s an entirely on-site process, from pouring the foundation to framing the walls, running the utilities, and installing the finishes. The primary advantage of stick-building is nearly unlimited customization. If you can dream it (and your architect can draw it), it can be built. However, this flexibility comes with significant trade-offs: long timelines of 8-14 months or more, vulnerability to weather delays, and higher, less predictable labor costs that can lead to budget overruns. For a full cost picture, see our guide on ADU Construction Cost.

The “Prefab” Family Explained

“Prefab” is an umbrella term that stands for prefabrication. It refers to any structure that has components built in a factory before being transported to the final building site. This off-site construction process is inherently more efficient, precise, and less wasteful than building outdoors. The history of prefab dates back centuries, but modern technology has transformed it into a high-quality, sophisticated solution. Prefab methods include modular, kit (or panelized), and manufactured homes. These modern solutions are rapidly changing California backyards, as detailed in our look at Prefab Granny Flats in California.

What is a Modular ADU?

A modular adu is a specific and advanced type of prefab construction. With modular, entire three-dimensional sections of a home—or “modules”—are built in a factory. These aren’t just walls; they are volumetric boxes that are often 80-95% complete when they leave the facility. This includes installed insulation, drywall, plumbing, electrical wiring, windows, doors, and even cabinetry and fixtures. Once completed, the modules are wrapped for protection, transported to your property on flatbed trucks, and then lifted by a crane onto a permanent foundation. The final on-site work involves “stitching” the modules together, connecting the utilities, and completing any exterior finishes. Critically, modular ADUs are built to the same local and state residential building codes as stick-built homes, ensuring they are permanent, high-quality structures that appraise just like a traditional home. Learn more in our article on ADU Modular Homes.

Kit (Panelized) vs. Manufactured ADUs

Two other common prefab types are kit and manufactured ADUs, and it’s important not to confuse them with modular.

- Kit ADUs (Panelized): In this method, the factory produces flat panels for the walls, floor, and roof. These panels are then shipped to your property like a giant IKEA set and assembled on-site by a contractor. This is faster and more precise than cutting lumber on-site for a stick-built home, but it still requires significantly more on-site labor and time to assemble and finish compared to a modular ADU.

- Manufactured ADUs: These are what many people used to call “mobile homes.” They are built on a permanent steel chassis to a federal standard—the HUD code—not local residential building codes. This is a key distinction. While often the most affordable option, they may have more design limitations, can be more difficult to finance with traditional mortgages, and can sometimes face different permitting and zoning challenges. Their value may also depreciate differently than a home built to local codes.

For a broader comparison of small living spaces, see our article on ADU vs Tiny House.

The Modular ADU Advantage: Speed, Cost, and Quality

The appeal of a modular adu isn’t just about being different; it’s about a fundamentally better value proposition. By leveraging a factory-controlled process, modular construction delivers significant, measurable gains in efficiency, predictability, and quality that traditional on-site construction struggles to match.

Accelerated Timelines: From Factory to Finish

Modular construction’s secret weapon is the parallel process. In a traditional build, everything happens sequentially: you can’t frame the walls until the foundation is cured, and you can’t do drywall until the roof is on. This linear path is long and vulnerable to delays. With modular, the work happens on two tracks simultaneously. While your foundation is being graded and poured on-site, your ADU is already being built in a factory. This simple overlap eliminates months from the schedule. Weather—the bane of every stick-builder—becomes a non-issue for 90% of the build. The result is 30-50% faster completion times. A project that takes a stick-builder 8-14 months can often be fully completed in just 4-6 months with modular. This incredible speed means you can house a family member or start generating rental income much, much sooner. Our ADU Building Process guide details these phases.

Cost-Effectiveness and Financial Predictability

Factory production is inherently more efficient, leading to significant savings that are passed on to the homeowner. These savings come from multiple sources: reduced on-site labor hours, bulk purchasing of materials at a discount, and minimal waste due to precise, computer-aided manufacturing. Perhaps most importantly, many modular providers offer fixed pricing for the unit itself. This protects you from the surprise change orders and cost overruns that are notoriously common in traditional builds, where unforeseen site conditions or material price spikes can blow a budget. A modular adu generally costs between $200 and $800 per square foot all-in, often making it up to 25% more affordable than a comparable stick-built unit. This financial predictability provides invaluable peace of mind and allows for a much clearer return on investment calculation. For more detail, see our ADU Cost Per Square Foot analysis.

Superior Quality Control and Sustainability

Building a home indoors simply produces a higher-quality product. Materials are protected from rain, sun, and humidity, preventing warping, mold, and degradation. Factory assembly lines use precise jigs and laser guides, ensuring every wall is square, every cut is perfect, and the entire structure is built to tight tolerances. This creates a tighter, more energy-efficient, and more durable home. Furthermore, modules are often built with steel frames and are engineered to withstand the stresses of highway transport and being lifted by a crane, making them incredibly robust—often stronger than a comparable stick-built home. Rigorous, multi-stage inspections by both in-house and third-party inspectors are standard practice, catching any potential issues long before the unit ever leaves the factory. Environmentally, this process is a clear winner. It generates far less material waste; one study found modular methods could cut material waste by 6,395 metric tons over 3,500 units. Many units also feature advanced energy efficiency packages, exceeding California’s strict Title 24 standards and lowering your utility bills for years to come. Explore more ideas in our Sustainable ADU Designs article and read about modular construction and sustainability.

Customization and Design Flexibility

The old stereotype of modular homes being bland, “cookie-cutter” boxes is completely outdated. Modern modular adu construction offers extensive design flexibility that satisfies the vast majority of homeowners. The process typically starts with a selection of proven, well-designed floor plans, which you then customize to fit your personal style and property needs. You can choose from a wide range of exterior finishes (such as wood siding, stucco, fiber cement, or metal), various roofing styles and materials, and multiple window and door placements. Inside, the choices are just as broad: you select your flooring, cabinets, countertops, tile, fixtures, and paint colors. While you may not have the unlimited freedom to move structural walls as you would in a ground-up custom stick-built project, the available options are vast and allow you to create a beautiful, personalized home at a fraction of the cost and time. Browse our Modern ADU Floor Plans for inspiration.

Navigating the Build: The Modular ADU Construction Process

Building a modular adu is a remarkably streamlined and transparent journey that combines the precision of factory manufacturing with the necessary steps of on-site preparation. While it’s much faster than traditional construction, it’s still a significant project. Understanding the key stages helps you know what to expect and how to partner effectively with your chosen provider. Here’s a breakdown of the typical process from start to finish.

Step 1: Design, Permitting, and Site Feasibility

This crucial initial phase turns your vision into a buildable, fully-approved plan. It begins with selecting a modular provider and undergoing a detailed site evaluation. A specialist will visit your property to assess factors like topography, soil conditions, utility access points (sewer, water, electric), and, critically, access for delivery trucks and a crane. This feasibility check ensures a modular unit can be safely and cost-effectively installed. Next, you’ll work with the provider’s design team to finalize your ADU. You’ll select a floor plan and customize your interior and exterior finishes. Once the design is locked, the permitting process begins. Many modular ADUs come with pre-approved state plans (sometimes called “master plans”), which can significantly speed up local approvals for the unit itself. However, your provider will still need to create and submit a site-specific plan for your property, covering the foundation, utility connections, and site layout to secure local building permits. Our ADU Permit Process guide offers more detail on navigating this stage.

Step 2: Factory Fabrication and Site Preparation

This is where the magic of modular’s parallel workflow happens. As soon as your permits are issued, two processes kick off simultaneously. In a climate-controlled factory, skilled craftspeople begin fabricating your ADU modules. This is a sophisticated assembly-line process where framing, wiring, plumbing, insulation, and even drywall and cabinetry are installed with precision and subjected to constant quality checks. At the exact same time, a local construction crew begins work in your backyard. This on-site work includes grading the land, trenching for utility lines (water, sewer, gas, electrical), and pouring a permanent foundation. The foundation is typically a concrete slab-on-grade or a raised perimeter foundation with a crawl space, engineered specifically for the modular unit’s connection points. This parallel workflow is the primary reason modular construction cuts months off the total project time. Learn more about site requirements in our ADU Building Requirements resource.

Step 3: Delivery, Installation, and Finishing

Installation day—often called “set day”—is fast, dramatic, and exciting. The completed modules, protected by weatherproof wrapping, arrive on trucks. A large crane is positioned to carefully lift each module and precisely place it onto the prepared foundation. A skilled crew guides the placement, ensuring a perfect fit. Once all modules are set, the crew begins the “stitch” work. This involves securely connecting the modules to each other and to the foundation, and sealing all seams to make the structure watertight. They also connect the interior plumbing and electrical systems between modules. The final steps involve hooking the entire ADU up to the main utility lines trenched during site prep. After passing a series of final inspections from local building authorities, your modular adu is officially granted a Certificate of Occupancy and is ready for you to move in.

Codes, Certifications, and Lifespan of a Modular ADU

A modular adu is a real home in every sense of the word, not a temporary or mobile structure. They are legally required to be built to the same state and local residential building codes as traditional stick-built houses. In California, this means complying with the California Building Code, Title 24 energy standards, and all local zoning and safety ordinances. This adherence is crucial for securing financing, obtaining property insurance, and ensuring strong resale value—your modular ADU will appraise just like a site-built home. Because they are built in a controlled environment with high-grade materials and are often over-engineered to withstand transport, they are incredibly durable. Many manufacturers state a service life of 60 years or more, making a modular ADU a sound, long-term investment in your property. For more on building standards, see our California ADU Guidelines article.

The Big Picture: How Modular ADUs Are Reshaping Housing

Beyond the benefits for individual backyards, the rise of the modular adu offers powerful solutions to some of California’s most pressing housing challenges. This construction technology is not just creating homes; it’s creating new opportunities for homeowners, fostering community resilience, and gently reshaping our neighborhoods for the better.

Solving the Housing Shortage and Increasing Density

For decades, California has faced a severe housing shortage, driving prices to astronomical levels. Modular ADUs directly address this crisis by adding new housing units to existing residential lots. This approach, often called “gentle density,” increases the housing supply without the need for large, disruptive, and often controversial multi-family developments. It utilizes existing infrastructure like roads and utilities, making it a highly efficient and sustainable way to grow. Because modular construction is so fast, it can bring new, high-quality housing online in a matter of months, not years, making it a uniquely responsive tool for meeting urgent community needs. This efficient use of land is a practical and popular path forward, as explored in our ADU Urban Design article.

A Smart Investment: Rental Income and Property Value

A modular adu is a financially compelling asset that can be a cornerstone of your financial strategy. In many parts of California, a well-designed backyard rental unit can generate $2,000 to $3,500 or more per month, providing a significant income stream to offset your mortgage, pay down debt, or boost your savings. Furthermore, adding a permitted, permanent ADU instantly increases your property’s value. Appraisers recognize ADUs as valuable additions, and homes with ADUs are highly sought after in the real estate market. The cost-effectiveness and predictable pricing of modular construction mean you are building this income-generating asset for less, leading to a faster and higher return on investment. You can Calculate your potential rental income and explore our ADU Return on Investment guide for a full financial breakdown.

Supporting Multi-Generational Living and Flexible Lifestyles

Modern life is dynamic, and family needs evolve. ADUs provide life-changing flexibility. For families practicing aging in place, a backyard cottage allows elderly parents to live with dignity and independence while remaining close to family for support and connection. For adult children struggling with high housing costs, an ADU can be an affordable stepping stone to financial independence. Beyond family, the rise of remote work has made the backyard ADU an ideal solution for a dedicated home office, creative studio, or personal gym, providing crucial separation between work and life. This adaptability makes ADUs invaluable for navigating life’s transitions, a topic we cover in our Multi-Generational ADU article.

Government Incentives and Financing Support

Recognizing the power of ADUs, California lawmakers actively support their construction. The CalHFA ADU Grant Program, for example, offers eligible low-to-moderate income homeowners up to $40,000 to cover pre-development and non-recurring closing costs. These costs include things like architectural designs, permits, and soil tests, which can be a major hurdle for many. You can learn more directly from the official CalHFA website. This grant, combined with a wave of pro-ADU legislation that has streamlined permitting, waived certain fees, and relaxed parking requirements, makes it easier and more affordable than ever to build. In response, a growing number of lenders are now offering specialized ADU construction loans and financing products tailored to the unique cash-flow needs of the modular process. Our ADU Financing Options guide provides a comprehensive overview.

Frequently Asked Questions about Modular ADUs

Considering a modular adu for your property? It’s natural to have questions. This is a significant investment, and the process is different from what many homeowners are used to. Here are straightforward, detailed answers to the most common questions we hear from homeowners across California.

How much does a modular ADU cost?

A complete, turnkey modular adu project typically costs between $150,000 and $400,000+. The final price is influenced by the unit’s size, the level of interior and exterior finishes you choose, and your specific site conditions. The price per square foot generally ranges from $200 to $800. It’s crucial to understand the two main cost components: the cost of the ADU module itself from the factory, and the “site costs.” Site costs can add $40,000 to $100,000 or more to the total project cost. These include essential services like:

- Soft Costs: Architectural plans, engineering, and permit fees.

- Site Prep: Grading, excavation, and foundation work.

- Delivery & Installation: Transportation of the modules and crane rental for setting the unit.

- Utility Hookups: Trenching and connecting to water, sewer, electrical, and gas lines.

- Finishing: Decks, stairs, landscaping, and any necessary site repairs.

Always ask for a detailed, all-in estimate that clearly separates the factory cost from the site costs. For a detailed breakdown, review our guide on ADU Building Costs.

How long does it take to build a modular ADU?

From the day you sign a contract to the day you get your keys, most modular ADU projects take 4 to 9 months. This is significantly faster than the 8-14+ months typically required for traditional stick-built construction. The timeline breaks down roughly into these phases:

- Phase 1: Design & Permitting (1-4 months): This is often the most variable phase, as it depends on how quickly you make design decisions and the processing time at your local building department.

- Phase 2: Factory Fabrication & Site Prep (2-4 months): This is the parallel-path stage where the factory builds your unit while a local crew prepares your site. The timeline is highly predictable.

- Phase 3: Installation & Finishing (2-4 weeks): This final phase includes delivery, setting the unit, connecting utilities, and passing final inspections. It is remarkably fast.

Are modular ADUs customizable?

Yes, absolutely. The idea that modular means “one-size-fits-all” is a persistent myth. While you will likely start with a portfolio of proven standard plans (which helps keep costs down and quality high), modern modular companies offer extensive options to personalize your unit. Customization typically includes:

- Exterior Finishes: Choose from various siding materials (wood, stucco, metal, fiber cement), roofing types, and a full range of color palettes.

- Interior Selections: You’ll select your flooring (hardwood, LVP, tile), cabinet styles and colors, countertop materials (quartz, granite), light fixtures, plumbing fixtures, and interior paint.

- Layout Adjustments: While structural walls are usually fixed, many providers allow for moving non-structural interior walls, changing window and door locations, or adding features like built-in desks or storage.

While not as limitless as a fully custom, architect-designed stick-built home, modern modular ADUs offer more than enough flexibility to create a beautiful, functional space that perfectly reflects your style. Explore options with Custom ADU Builders.

Conclusion: Is a Modular ADU Right for You?

If you’re a California homeowner looking to add living space to your property, a modular adu presents a powerful and compelling case. It offers a smarter, faster, and more financially predictable path to achieving your goals than traditional construction. The core benefits are undeniable: accelerated speed that gets your project done in months, not years; predictable cost that protects your budget from unforeseen overruns; superior quality born from a controlled factory environment; and improved sustainability through reduced waste and enhanced energy efficiency.

For homeowners in California, a modular ADU is far more than just extra square footage. It’s a strategic financial investment that can generate thousands in monthly rental income, significantly boost your property value, and provide a rapid return on investment. It’s a flexible life solution for multi-generational living, offering a safe and independent space for aging parents, a launching pad for adult children, or a dedicated home office that adapts to your family’s changing needs.

Ultimately, your final decision will depend on your specific budget, desired timeline, property constraints, and personal priorities. However, the evidence suggests that for a growing number of people, modular is the most logical choice. The most critical step in this journey is choosing the right provider—a reputable, experienced partner who understands California’s complex building codes and can guide you seamlessly from the first design sketch to the final installation.

The housing landscape is changing, and modular ADUs are at the forefront of that evolution. They offer a practical, forward-thinking solution for homeowners seeking to maximize their property’s potential and a significant market opportunity for builders ready to embrace the future of construction.

For builders and architects looking to capture this growing market, standing out requires a specialized marketing approach. At ADU Marketing Pros, we help construction and architecture firms attract high-quality leads by showcasing their expertise in this niche. Learn how to effectively market your Prefab ADU projects in Los Angeles and throughout California.