Understanding the True Cost of Your Prefab ADU Investment

As housing costs rise and families seek more flexible living solutions, the accessory dwelling unit (ADU), or granny flat, has emerged as a powerful investment. Prefabricated ADUs, in particular, offer a streamlined path to adding valuable space to your property. However, navigating prefab granny flat prices requires a clear understanding of what your money actually buys. Prices can range from an enticing $25,000 for a basic kit to over $300,000 for a complete, high-end installation. The most critical thing to understand is that the advertised price is rarely what you’ll actually pay. The gap between a kit price and the final “all-in” cost catches many homeowners off guard.

Quick Price Overview:

- Kit-Only Pricing: $25,000 – $75,000 (structure only)

- Complete Installation: $85,000 – $330,000 (turnkey projects)

- Cost Per Square Foot: $100 – $400+ (depending on finishes and location)

- Additional Costs: $20,000 – $100,000+ (for site prep, permits, and utilities)

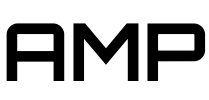

A $60,000 prefab kit can easily become a $150,000 project once you factor in foundation work, crane delivery, utility connections, and permits. The primary cost drivers are size, location, customization, and site conditions, which can swing your budget by tens of thousands of dollars. Unlike traditional construction, prefab offers more predictable pricing by reducing weather delays and material waste in a factory setting. However, you must budget carefully for the complete installation process. Understanding these factors upfront is the first step toward making an informed decision and avoiding budget surprises for your ADU project.

Know your prefab granny flat prices terms:

The “Kit Price” vs. The “All-In” Cost: Unpacking the Numbers

Understanding the difference between a “kit price” and a “turnkey” or “all-in” cost is the most crucial step in budgeting for your prefab granny flat. The advertised price for a modular unit often just covers the prefabricated structure itself—not a move-in ready home. Think of a kit as a car engine: it’s a vital component, but it needs a chassis, wheels, and an interior to become a functional vehicle.

The true cost, or “all-in” price, covers everything from preparing your backyard to hooking up utilities. For example, a 600 sq ft prefab ADU kit might be advertised for $25,000 to $75,000, but the total installed cost can easily reach $85,000 or more, even before permit fees. This leap is why getting the full picture upfront is so important.

What’s Included in the Base Price?

When a company quotes a price for a prefab granny flat “kit,” they are referring to the core components manufactured off-site. These elements are what make prefab construction efficient. Typically, a kit includes:

- The Prefabricated Structure: The main modular sections or panels.

- Wall Panels and Roof Trusses: The pre-cut and often pre-assembled structural framework.

- Standard Windows and Doors: Usually double-paned windows and pre-hung interior/exterior doors.

- Basic Structural Shell: The primary framework that gives the granny flat its shape.

- Weatherproofing: Exterior wraps and materials to protect the structure during transport and assembly.

These are the building blocks, but they don’t include the foundation, utility connections, or on-site finishing work.

Uncovering the “Hidden” Costs of a Prefab Build

These costs aren’t truly hidden, but they are additional expenses essential for making your granny flat functional, safe, and compliant with local regulations. You’ll need to budget for:

- Site Preparation and Excavation: This is far more than just clearing a patch of grass. It can involve soil testing to determine stability, extensive grading to create a level building pad, demolition of old sheds or concrete patios, and even tree removal. Costs escalate on sloped lots or properties with poor soil conditions.

- Foundation: Your choice impacts cost significantly. A concrete slab-on-grade foundation is often the most affordable for flat sites. However, on sloped or uneven properties, a raised foundation system with bearers and joists (or piers) can be more cost-effective by minimizing expensive excavation and earthmoving.

- Delivery and Crane Rental: Transporting modules from the factory is a given, but the final placement is a major variable. Crane rental is essential, and costs depend on the size of the crane needed and the duration of the lift. Difficult site access—such as narrow streets, overhead power lines, or a long distance from the curb to the backyard—can require a larger, more expensive crane or even a temporary road closure, adding thousands to the budget.

- On-Site Assembly: Often called “stitching” or “buttoning up,” this is the skilled labor required to join the modules, seal all connections against weather, and integrate the structure with the foundation. This is a precise process that ensures the home is seamless and structurally sound.

- Utility Connections: This is one of the biggest unknowns. The cost to extend sewer, water, and electrical lines from the main house or street to the ADU depends on the distance. Trenching through soft dirt is relatively cheap, but cutting through concrete driveways or navigating around existing landscaping is complex and costly. In some cases, the main home’s electrical panel or sewer line may need to be upgraded to handle the additional load, adding another layer of expense.

- Permit and Design Fees: These are non-negotiable costs dictated by your local city or county. They can include plan check fees, building permit fees, school district fees, and various impact fees. In areas with complex regulations like many parts of California, these government fees can range from a few thousand to over $20,000.

- Finishing Touches: While not always mandatory for occupancy, you should also consider costs for landscaping to blend the ADU with your yard, building pathways or a driveway for access, and adding fencing for privacy. These elements complete the project and improve its overall appeal and value.

Key Factors That Drive Your Prefab Granny Flat Prices Up or Down

Once you include every project phase, the final cost is influenced by your choices and property conditions. The beauty of prefab is that you control many of these levers, allowing for more predictable budgeting than with traditional construction.

Size, Bedrooms, and Layout Complexity

Square footage is the single biggest cost driver. A compact 600 sq ft unit will cost far less than a 1,200 sq ft model. The total cost per square foot, including all site work and finishes, typically lands between $200 and $400+.

- Bedrooms & Bathrooms: A 3-bedroom design is more expensive than a 1-bedroom studio because of the additional materials for interior walls, doors, and the extensive plumbing and electrical work required for bathrooms and kitchens.

- Layout & Storeys: Open-plan layouts may require more expensive engineered beams for support. Two-storey designs are more complex, requiring more structural engineering, intricate crane work for stacking modules, and additional site work for staircases, all of which raise the budget.

- Custom Floor Plans: Deviating from a manufacturer’s standard models is the quickest way to erode the cost savings of prefab. Custom plans require new engineering, drafting, and adjustments to the factory’s streamlined process, adding significant costs.

Material Choices and Finish Levels

Your taste in finishes can swing the budget dramatically. Manufacturers offer different tiers of materials, allowing you to balance aesthetics with cost.

- Exterior Cladding: Basic fiber-cement or vinyl siding is affordable and durable. Upgrading to engineered wood, natural timber, stucco, or brick veneer adds significant character—and dollars to the final price.

- Interior Finishes: Standard builder-grade options like vinyl plank flooring and laminate countertops are budget-friendly and resilient. Upgrading to engineered hardwood floors, porcelain tile, and quartz or granite countertops will lift the interior feel but can increase costs by thousands.

- Fixtures & Appliances: A standard appliance package and basic fixtures from brands like Moen or Delta will keep you on budget. Opting for high-end, smart appliances from brands like Bosch or Miele, along with designer lighting and plumbing fixtures, can add tens of thousands to the project cost.

Customization and High-Performance Upgrades

- Design Tweaks: Simple changes like moving a non-structural wall or changing a window size might seem small, but they can trigger an extra engineering review and disrupt the factory workflow, adding cost.

- Accessibility Features: Incorporating Universal Design principles, such as wider doorways, zero-threshold showers, and reinforced walls for future grab bars, adds a modest cost upfront but protects future resale value and makes the unit suitable for all ages and abilities, as recommended by the AARP.

- Energy Efficiency: Investing in upgrades like higher-rated insulation, triple-pane windows, and a high-efficiency HVAC system costs more initially but provides long-term savings on utility bills. The U.S. Department of Energy’s Energy Saver guidelines can help you estimate the payback period for these investments.

- Solar Readiness and Smart Home Tech: Pre-wiring for rooftop solar panels during fabrication is far cheaper than retrofitting later. Similarly, integrating smart home features like automated lighting, security systems, and climate control is most cost-effective when planned from the start.

Prefab vs. Traditional Construction: A Cost and Timeline Comparison

Many homeowners weigh the costs of prefab against traditional, on-site “stick-built” construction. While the final price tag can be similar, the process, timeline, and cost structure are very different. Prefabrication moves a significant portion of the construction process into a factory, which fundamentally changes the project’s efficiency and speed.

Comparing Prefab Granny Flat Prices to Stick-Built Homes

The cost-effectiveness of prefab comes from efficiency and control, not just cheaper materials. Key differences include:

- Labor Costs: With much of the work completed in a factory by a consistent, skilled workforce, on-site labor is significantly reduced. This streamlined process often leads to savings and avoids the scheduling headaches of coordinating multiple subcontractors.

- Controlled Environment: Building indoors eliminates weather delays, ensures consistent quality control, and allows for the use of specialized equipment, reducing costly errors and material damage.

- Reduced Material Waste: Factories purchase materials in bulk and use computer-aided manufacturing to optimize cuts, resulting in significantly less waste compared to a traditional job site. This is both cost-effective and environmentally friendly.

- Predictable Pricing: Manufacturers can provide a firm, transparent cost for the structure itself, offering greater budget certainty than the estimate-based nature of stick-built projects, which are prone to cost overruns.

- Transportation: A unique cost to prefab is the transportation of modules and crane rental for placement. This is a significant line item not present in traditional builds.

- Durability: Prefab units are engineered to withstand the stresses of transportation over highways, a process that subjects them to forces similar to a small earthquake. This often results in a highly durable structure with superior structural integrity.

While a high-end prefab may cost as much as a custom stick-built ADU, the price transparency and predictability offer significant peace of mind.

The Value of Time: How Faster Builds Impact Your Bottom Line

Beyond direct prefab granny flat prices, time savings are one of prefab’s most compelling advantages. A traditional ADU can take six months to a year or more to complete, while a prefab unit can be manufactured in 6-8 weeks and installed on a prepared site in just days or weeks.

This speed offers several financial benefits:

- Fewer Weather Delays: Indoor factory construction keeps the project on schedule, regardless of rain, snow, or extreme heat.

- Faster Occupancy: You can house family members or start generating rental income much sooner. Missing out on six months of rent is a significant opportunity cost. If a comparable rental in your area is $2,500 per month, a six-month delay with traditional construction represents a $15,000 loss in potential income.

- Lower Loan Interest: A shorter construction period means you pay interest on a construction loan for less time. Shaving six months off your loan term can save you thousands of dollars in interest payments.

- Reduced Neighborhood Disruption: A traditional build means months of noise, dust, and construction traffic. A prefab installation condenses the major on-site work into a much shorter period, preserving peace for you and your neighbors.

Maximizing Value: ROI and Financing Your Backyard Investment

A prefab granny flat is more than an expense; it’s an investment in your property, lifestyle, and financial future. While the upfront prefab granny flat prices are significant, the long-term returns can be remarkable. An ADU creates value through multiple streams: generating rental income, increasing property value, and providing flexible housing solutions.

Calculating the Return on Investment (ROI)

The financial benefits of adding a granny flat are especially compelling in high-demand housing markets like California. Here’s how the investment pays off:

- Rental Income Potential: A well-located granny flat can generate $300-$700 per week, providing a steady income stream that can deliver a 10-20% ROI for investors. This income can often cover the financing payments for the project.

- Increased Property Value: Studies show that adding a functional, independent living unit can increase a home’s value by up to 30%. This adds real equity you can leverage later.

- Alternative to Aged Care: For families with aging parents, a granny flat is a cost-effective alternative to expensive aged care facilities. According to Genworth’s Cost of Care Survey, assisted living costs can be substantial, making an ADU a financially savvy long-term solution that keeps family close.

- Tax Depreciation Benefits: If you use the granny flat as a rental property, you may be eligible for significant tax depreciation deductions, further enhancing your financial return.

How to Finance Your Prefab Granny Flat

Several financing options can make your granny flat project a reality. The best choice depends on your financial situation and equity.

- Home Equity Line of Credit (HELOC): A flexible option if you have equity in your home. You borrow against it as needed and only pay interest on the amount you use, which is ideal for phased construction payments.

- Cash-Out Refinancing: You refinance your existing mortgage for a larger amount and use the difference to fund the project. This is especially smart if you can secure a lower interest rate.

- Construction-to-Permanent Loans: These loans are designed for building projects. They start as a construction loan and convert to a permanent mortgage once the ADU is complete, streamlining the process.

- Personal Loans: For smaller projects or those who prefer an unsecured loan, personal loans offer quick access to funds, though typically at higher interest rates.

- Manufacturer Financing: Always ask your prefab provider if they offer direct financing programs or have partnerships with lenders familiar with prefab construction.

Before committing, consult a financial advisor to understand the tax implications and choose the best strategy for your long-term goals.

A Look at Prefab Price Tiers: What Can You Get for Your Money?

Prefab granny flats span a wide price spectrum. Matching your budget with realistic expectations is the fastest way to avoid sticker shock. These tiers represent total, installed pricing—not just the kit.

Budget-Friendly Kits & Basic Builds (Under $100 K)

- What You Get: A $25 K–$75 K kit plus some DIY site work. Hitting an all-in cost below $100 K usually requires hands-on labor from the owner.

- Typical Size: Studios or small 1-bedroom units under 600 sq ft.

- Finishes: Builder-grade surfaces (laminate, vinyl). Utility hookups, permits, and foundations are extra.

Mid-Range Turnkey Projects ($120 K–$200 K)

- What You Get: A turnkey service that bundles the unit, delivery, installation, and standard site work.

- Typical Size: 600–900 sq ft with 1–2 bedrooms—ideal for rental income or multigenerational living.

- Finishes: Durable, mid-tier materials chosen for value and longevity.

Premium & Custom Builds ($200 K+)

- What You Get: Larger footprints (900–1,200 sq ft), two-storey options, or challenging sites that demand bespoke engineering.

- Finishes: Luxury specifications—quartz or granite, hardwood floors, designer fixtures, top-line appliances.

- Why Pay More?: Complex sites, strict HOA aesthetics, or a need to maximise rental income can justify the spend while boosting resale value.

Where you land on this spectrum depends on your priorities: sweat-equity savings, hands-off convenience, or high-end customisation.

Conclusion: Planning Your Budget for a Successful Build

Your prefab granny flat prices journey begins, not ends, with the advertised price. A realistic budget must look beyond the brochure and account for the complete picture: the unit, site preparation, foundation, utility connections, permits, and finishes.

The beauty of prefab construction lies in its predictability. The factory-controlled process minimizes surprises, weather delays, and cost overruns common in traditional builds, leading to more reliable timelines and budgets.

Careful upfront planning is the key to a successful project. Start by defining your goals—whether housing family, generating rental income, or adding flexible space—and get comprehensive quotes that cover the entire scope of work. You are not just building a structure; you’re creating a valuable asset. A well-designed ADU can generate $300-$700 weekly in rent and increase your property value by up to 30%.

With a faster construction timeline, you can enjoy these benefits much sooner. A prefab ADU can be move-in ready in a fraction of the time it takes for a traditional build, putting rental income in your pocket or a home in your backyard months earlier.

At ADU Marketing Pros, we help top ADU builders communicate their value clearly, ensuring homeowners like you understand the full scope and long-term benefits of their investment.